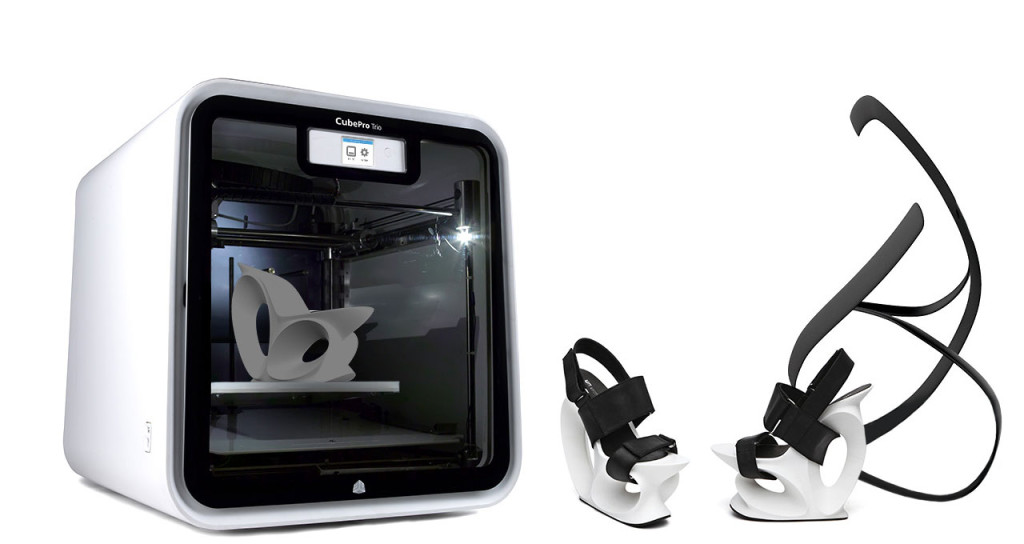

*some layers are also not 'stacked' straight maybe call it as little as 15% but as much as 90%. features - I've made a few that seem to build with the -entire- surface on the inside of the desired contour(making it undersize by layers*layerwidth) *'bow strings'- surfaces that do not adhere to surrounding layers and/or are pulled tight between the start & end of an arc. don't think I've tried spherical shapes yet). Some problems come with round surfaces most obviously (radius/fillets. I did have my first 'rook' built within a few hours of signing the freight receipt. That is surely one point of praise I can give the crew at 3D systems/Cubify.

#Cube pro 3d systems download

Because I CAN toss an *.STL file at the printer out of the box, it'll build it (specifically the 'free sample files' you can download from them). and they went wifi/adhoc instead of ethernet.

#Cube pro 3d systems software

If I used the word 'hate' it would probably be the slicer software that I'm forced to use. :/ So yeah, a guy I know built a Mach3 based CNC gantry mill out of a workbench from pieces so I do have a little info/experience there. To use all features as it's currently setup I need 7 motor capability+1 extra hot tip which I can't seem to find. Ignoring anything to do with heaters that I could just wire to switches. You've seen one problem I didn't bring up & why I wanted to just buy the $500 controller from Motion Control. maybe need some more info I left out, or just an idea of something to try. If you have any experience with CNC/stepping motor control etc.

I've been waiting for replacement parts, during the down time on that extruder I've run part of a $20 spool through another and didn't see a difference between the two materials on the finished parts. This would also resolve the asinine proprietary cartridges they do which seems to be pretty cheap filament times the price. Bypassing any modifications 3D systems made and just processing Gcode from a open source slicer. So with that I was wondering if anyone here knew if that would be a plug & play option. Their pendant controller seems to be exactly what is in the base of my printer. When I open one of their files in notepad I get pages of garbage. I've tried using Slic3r and KISSlicer and if I change the file extension(to *.gcode etc) I can get the machine to 'see' the file, but it will not run it. There are some points I didn't like from the beginning but thought it would be worth it if it worked as advertised. So I'm looking into options, some points I'm having issues with failed prints/slices, machine alarms, grinding.

#Cube pro 3d systems update

Some problems being reduced to "software issues" but went silent when asked if they were were known issues or when a update may be available.

Having troubles with it, customer support has been good some days but getting me nowhere. no returns, no refunds -90day warranty (I knew before, just saying) Hi I'm pretty new to 3D printing and here's my spew.īought a 3D systems Cube Pro Trio.

0 kommentar(er)

0 kommentar(er)